EPE EPS Foam Recycling Machine

The Shuliy foam recycling machine processes waste EPE EPS foam into pellets, which can be processed into a form that is easier to store and saves space for transportation. This article mainly introduces the related foam recycling machine and the working principle and so on.

Our foam recycling machine is capable of processing waste foam into plastic pellets for easy reuse. The whole plastic foam pelletizing line contains several key machines, which mainly include a styrofoam shredder, foam granulator, and plastic pellet cutting machine. Next, we will introduce the EPS EPE foam recycling process and related styrofoam recycling machines in detail.

Foam Pelletizing Process

Due to the differences in material characteristics, the pelletizing processes for EPS and EPE foam vary. For larger EPS foam, it first needs to be crushed into smaller pieces using an EPS foam shredder, then fed into the EPS pelletizing machine, where it is melted and extruded into long strands. After cooling, the strands are cut into small pellets by a cutter.

In contrast, EPE foam is softer, and since the EPE granulator has a built-in feeding system, there is no need for a crusher. Each type of foam requires a specific processing method to ensure efficient recycling and reuse.

EPE EPS Foam Granulation Video

Features of Foam Recycling Machine

- Compact design, easy to operate, suitable for all kinds of plant space.

- Equipped with a precise temperature control system to ensure stable temperature and high quality of granules during the granulation process.

- Provide a variety of EPS recycling methods including granulation, hot melt, and cold press to meet different needs.

- Provide tailor-made equipment solutions to enhance production efficiency according to customer needs and site conditions.

Styrofoam Recycling Machine Raw Materials

The styrofoam recycling machine can process pearl cotton, insulated boxes, disposable foam lunch boxes, EPE fruit foam nets, S-shaped white packing peanuts, foam pads, foam packaging materials, and so on. It can process many types of foam raw materials such as EPE, EPS, etc. It provides an effective solution for the recycling of waste foam.

Final Product

After crushing and pelletizing processes, waste foam materials can be processed into plastic pellets, as shown in the figure below.

plastic foam pelletizing line Equipment

Styrofoam Shredder Machine

Discarded foam is usually fluffy and occupies a larger volume. Plastic foam crushers can help increase the efficiency of reuse by breaking up the foam into smaller particles. The fragmented foam is more easily heated, compressed, or pelletized in subsequent processes to convert it into recycled feedstock.

The crusher blade material for the 45 steel, with good wear resistance and high strength, can effectively improve the cutting efficiency and extend the service life.

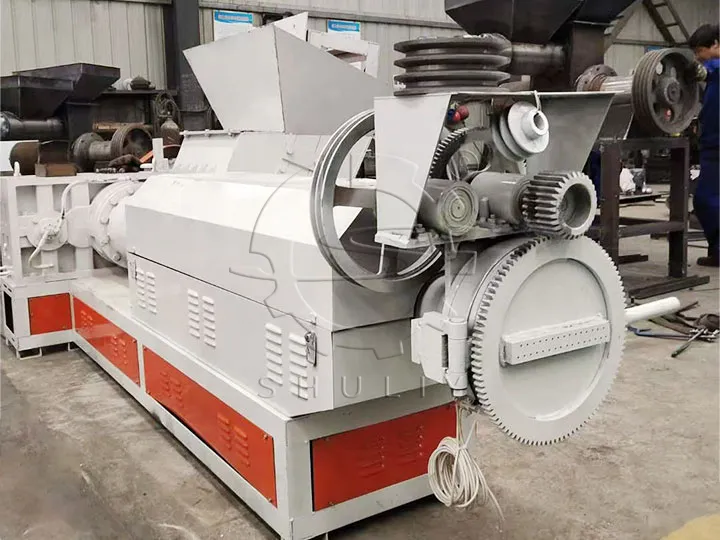

Plastic Foam Granulator

The waste foam material is heated and melted through the machine and extruded in long plastic strips through the die head. We have two types of machines, EPS pelletizer and EPE granulator, which are specialized in these two types of materials.

The pelletizer with an automatic temperature control system, using heating ring heating, can accurately control the temperature, to ensure that the plastic in the processing process of uniformly melting, to enhance the effect of granulation and product quality.

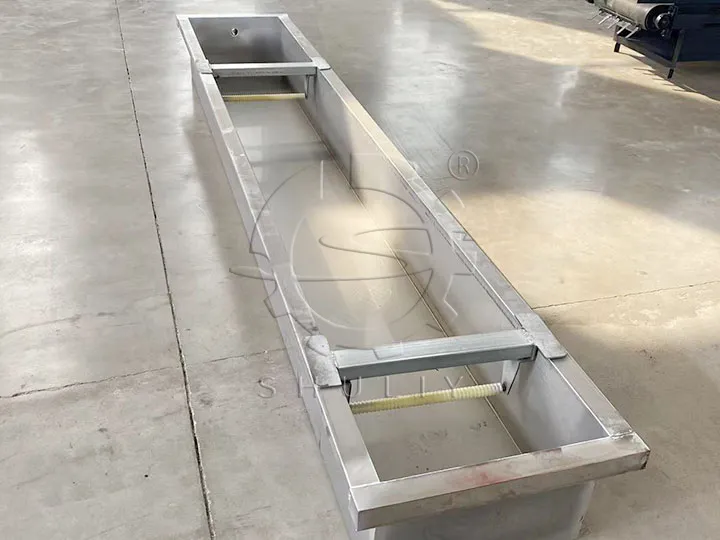

Plastic Cooling Tank

Cooling tanks are used to cool and solidify long strips of plastic extruded from the foam granulator for subsequent cutting into smaller pellets.

Plastic Pellet Cutting Machine

This plastic pellet cutting machine is used to cut long strips of plastic into uniformly sized pellets.

Parameters of Styrofoam Recycling Machine

| Parameter | Details |

| Machine Type | EPS/EPE Foam Recycling Machine |

| Main Components | Foam Crusher, Granulator, Pellet Cutting Machine |

| Capacity | Varies by machine (e.g., 150-200 kg/h for pelletizer) |

| Temperature Control | Equipped with an automatic temperature control system |

| Heating System | Heating ring |

| Material Processed | EPE, EPS |

| Recycling Methods | Granulation, hot melting, cold pressing |

| Customizability | Custom equipment solutions available based on site and production needs |

Other Foam Recycling Machines

EPS Hot Melting Machine

The EPS hot melting machine is used to heat and melt the EPS waste, and at the same time use the pressure system to extrude the melted EPS plastic to form a homogeneous molten mass. The volume can be reduced for subsequent storage, transportation, and reuse.

Styrofoam Compactor Machine

The main function of the styrofoam compactor machine is to compress waste EPS foam, reducing its volume significantly and converting it into reusable raw materials, such as higher-density blocks.

Foam Recycling Machine Related Cases

EPS Hot Melting Machine Shipped to Malaysia

Malaysia customer ordered a SL-1000 hot melt machine with a capacity of 200-250kg/h. The following picture shows the delivery of the machine.

More details: Malaysia Customer Ordered An EPS Hot Melting Machine

Styrofoam Compactor Machine Exported to USA

The American customer ordered an SL-400 model foam compactor with a capacity of 300kg/h. The following picture shows the packing and transportation of the machine.

More details: Foam Compactor Machine Shipping To The United States

Contact Us For Foam Recycling Solutions

If you are looking for an effective foam recycling solution, we would like to help. All of our team can provide you with expert advice and support. By contacting us, you can get a personalized solution for your specific needs.