PET Bottle Recycling Plant

PET bottle recycling plant is a specialized equipment for recycling and processing waste PET bottles into bottle flakes. This article is a detailed introduction of PET bottle washing line This article is a detailed introduction to PET bottle washing line, including configuration, recycling process, parameters, cases and so on.

PET bottle recycling plant is a specialized equipment for recycling and processing waste PET bottles into bottle flakes. Through this line, we can efficiently convert waste PET bottles into high-quality bottle flakes for the re-production of PET bottles or other related products.

Our PET bottle washing line has an excellent production capacity of 500kg to 6000kg per hour, and we can customize the line’s equipment configuration and capacity according to customers’ needs. As a PET bottle recycling machine manufacturer, we not only provide complete line equipment but also include technical support and after-sales service to ensure that our customers are fully supported and safeguarded during the recycling process.

3D Video of PET Bottle Recycling Process

This video shows the recycling process for a 1000kg per hour PET bottle washing line. In addition, we offer solutions for larger capacities, such as a line that processes 3000kg per hour.

Advantages of Plastic Bottle Recycling Plant

- High configuration flexibility to maximize space and equipment resources.

- High production capacity to meet the needs of various scales of production.

- Through the multi-stage washing and separation process, PET bottle recycling plants can produce high-purity PET bottle flakes with high market value.

- Providing tailor-made solutions to ensure optimum cleaning results and economic efficiency.

PET Bottle Recycling Plant Introduction

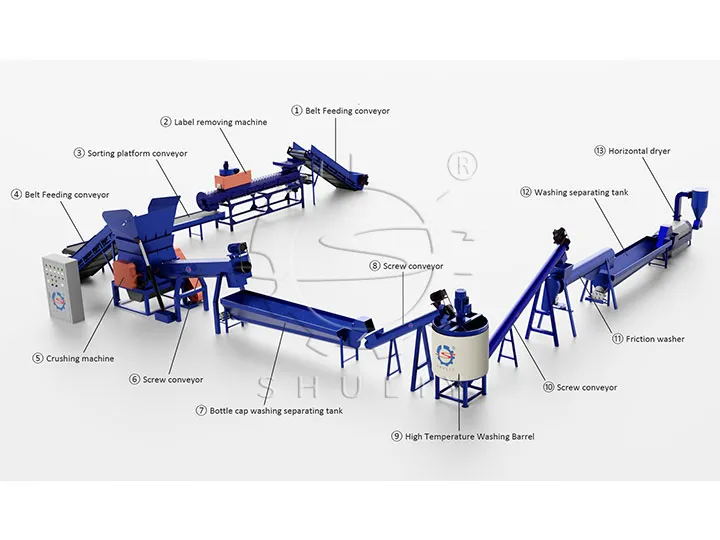

PET bottle washing line is a complete solution for PET bottle recycling, including a PET bottle label remover machine, PET bottle shredder, sink float separation tank, PET flakes hot washing machine, PET friction washing machine, and PET flakes dryer machine. The production line can not only recycle common PET bottles such as mineral water bottles, beer bottles, and beverage bottles, but also process all kinds of PET containers, such as food packaging bottles and cleaning products bottles.

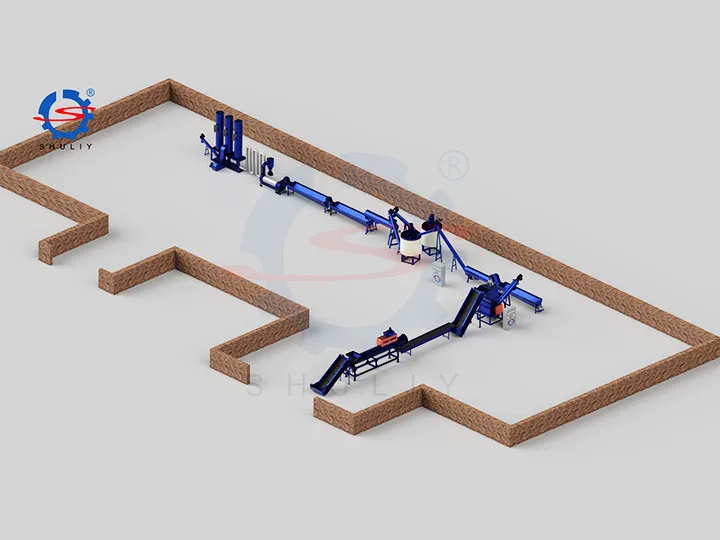

Customized PET Bottle Washing Plant

We are committed to providing customized PET bottle recycling plant solutions, not only can we customize the configuration, output, and appearance of the recycling line according to the customer’s needs, but we can also design a suitable PET bottle washing line placement plan according to the customer’s plant size and layout needs.

Regardless of the size of the customer’s plant, we can customize the optimal layout of the PET bottle recycling plant to make full use of the space ensure efficient operation of the equipment, and maximize production efficiency. Through well-designed placement solutions, we can not only maximize production efficiency, but also optimize workflow, improve equipment utilization, and bring greater convenience and benefits to our customers’ production operations.

Raw Material And Final Products

The PET bottle recycling plant is capable of processing used PET bottles such as cola bottles, beverage bottles, mineral water bottles, etc., and processing them into high-quality bottle flakes that can be used to produce PET bottles or other related products again. Through sophisticated processing technology, we ensure that the quality of bottle flakes produced is stable and meets the relevant standards and requirements. The following are the standards for PET flakes produced by this recycling line.

- Moisture content: <0.5-1%

- pH: <8.0

- PVC content: < 100ppm

- PE/PP content: < 200ppm

- Impurity content: ≤300-500mg/kg

- Powder content: ≤ 2000-3000mg/kg

- Particle size: < 16-18mm

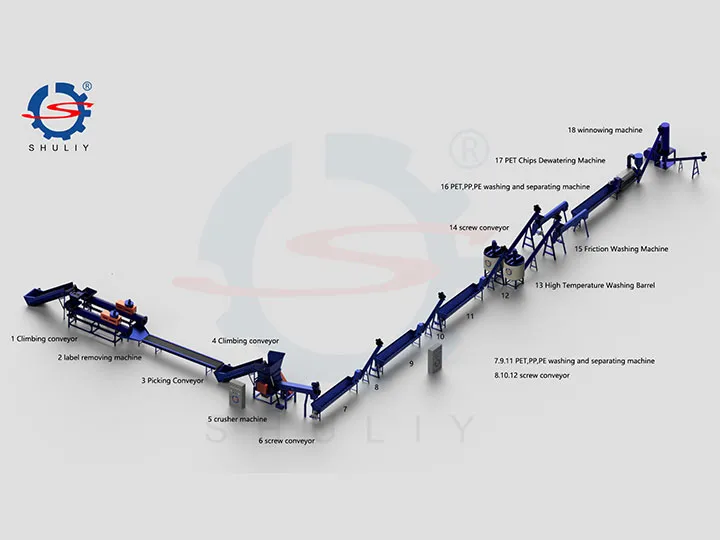

PET Bottle Washing Plant Workflow

The PET bottle recycling process includes steps such as de-labeling, shredding, floatation and sinking separation, hot washing, friction washing, and drying. Each step is carefully designed and adjusted to ensure optimal recycling results and productivity. From waste PET bottles to usable flakes, the entire process is efficient and environmentally friendly.

The process can be optimized and adapted to actual needs or production volumes. For example, two hot wash tanks can be used when processing larger volumes and two rinsing steps can be added after the hot wash tanks to ensure effective cleaning.

Key PET Bottle Recycling Machine

PET bottle label remover machine: This machine is designed specifically to remove labels from PET bottles. Equipped with multiple carbide blades, it efficiently removes labels by rotating and cutting. Round bottles can achieve a label removal rate of 98%-99%, while flat bottles typically reach 85%-90%.

PET bottle shredder: The machine is specially designed to crush PET bottles into flakes for subsequent washing. The blade material of this crusher is 9Crsi and the screen size is 16-18mm.

Sink float separation tank: The machine separates PET bottle flakes from PP, PE caps, or PVC labels. PET sinks due to its higher density, while PP and PE float. A screw conveyor at the bottom of the cleaning machine moves the PET flakes forward.

PET flakes hot washing machine: The machine effectively cleans and decontaminates bottle flakes using hot water and detergent, usually at a temperature of 85°C to 95°C. The machine can also be used to clean and decontaminate bottles and flakes.

PET friction washing machine: The function of the machine is to subject PET flakes to friction and water in a rotating drum or chamber. This helps to remove stubborn contaminants from the surface of the bottle flakes. This friction washer is usually placed at 45 degrees for better drainage.

PET flakes dryer machine: The machine utilizes centrifugal force to effectively remove water from PET bottle flakes, which can control the water less than 3%-5%, plus drying pipes to control the water less than 0.5%-1%.

Specifications of PET Bottle Recycling Plant

| Capacity | 500kg/h-6000kg/h |

| Raw materials | PET bottles of various sizes |

| End products | Recycled PET flakes |

| PET bottle flake applications | Granulation, fiber production, blow molding, injection molding |

| Mandatory accessories | Shredder blades, screens, grinders, cleaning powders |

| Optional equipment | Drying tubes, air separators |

| Customizability | Customizable |

| Installation methods | Online guidance or on-site assistance |

PET Bottle Washing Line Tips

- De-labeling separation: Flat bottles and round bottles should be de-labeled separately because of the different knives used.

- Crushing water: when crushing need to use a lot of water to rinse sediment, to prevent contamination of subsequent cleaning.

- Blade maintenance: Sharpeners keep blades sharp and regular maintenance extends equipment life.

- Deep water tank option: When the bottle pieces are thin, the use of a deep water tank will help the bottle pieces to sink.

- Hot washing: Hot wash pot with cleaning powder or lye to effectively remove stubborn stains.

- Moisture control: add drying pipes after the dryer to control the moisture at 0.5%-1%.

- Wind separation: The wind separator separates fine labels and dust to enhance the purity of bottle flakes.

- Drying support: drying pipes need to be installed before the air separator to ensure that the material is dry.

PET Bottle Recycling Plant Working Video

Plastic Bottle Recycling Machine For Sale

PET Bottle Recycling Project In South Sudan

This customer in South Sudan produces bottled purified water and beer and has accumulated a large number of waste and expired bottles. The customer wants to process these bottles into PET pellets for re-blowing. We customized a solution for the customer and sent an engineer to the customer’s plant to assist with the installation.

More details can be viewed: PET Plastic Recycling Machine Installed In South Sudan To Produce Recycled Resin

500kg/h PET Flakes Making Machine Exported To Nigeria

Below is a customised PET flakes making machine for a customer in Nigeria, with an output of 500kg/h. The final PET flakes are 10-12mm in size and are used for making staple fibers.

More details can be viewed: Recycling Project In Nigeria: 500KG/H PET Recycling Machine Shipment

PET Bottle Recycling Machine Price

As a PET bottle recycling machine manufacturer, we are well aware of our customers’ concerns about the price of PET bottle recycling plants. We offer a wide range of PET bottle recycling machine models and configurations, with prices varying based on factors such as equipment specifications, capacity, and features.

We are committed to offering competitive prices and ensuring that the performance and quality of the equipment can meet our customers’ needs. We also offer flexible payment options and personalized after-sales service to ensure our customers receive the best experience and support during purchase and use. Welcome to contact us for more information about PET plastic recycling machine prices and details.