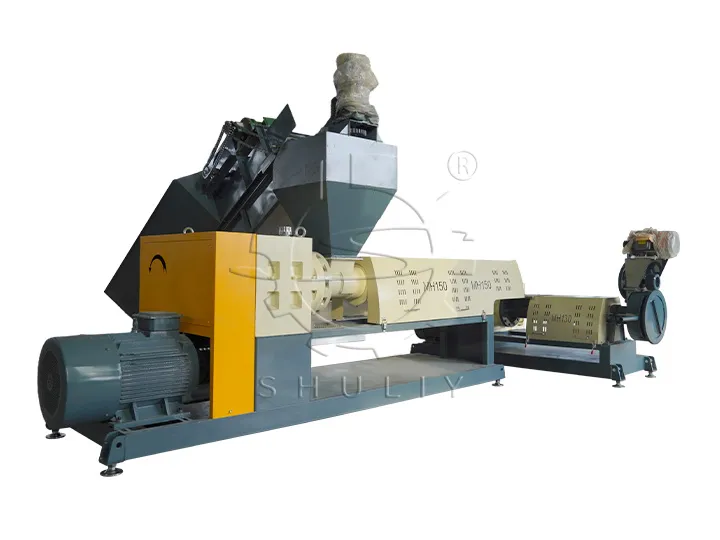

Plastic Pelletizing Machine

Plastic pelletizing machine is a key recycling equipment for processing waste PP PE PVC PS and other plastics into plastic pellets. The machine is available in a variety of models and configurations to meet the different output requirements of customers.

As the key equipment for plastic recycling, the plastic pelletizing machine plays an important role in the plastic recycling process. It can process all kinds of plastic wastes, such as plastic bottles, plastic bags, plastic containers, etc., into granular plastic raw materials, providing a reliable source of raw materials for the production of plastic products again.

Shuliy Machinery’s plastic pellet making machines are structurally stable, easy to operate, and suitable for production scenarios of all sizes. And there are a variety of models to meet the production needs of different customers.

Our equipment has been sold to many countries and received many customers’ favorable comments, if you need it, please feel free to contact us. Our professional sales managers will provide you with detailed product introductions, quotations, and technical support to ensure that you choose the most suitable equipment. At the same time, we also provide installation and commissioning services to help you quickly into production.

Working Video Of Plastic Granulator

Below is a video of plastic pelletizing in action, showing the complete process from feeding, heating and melting, extruding, and cooling to cutting.

Raw Materials Of Plastic Recycling Granulator

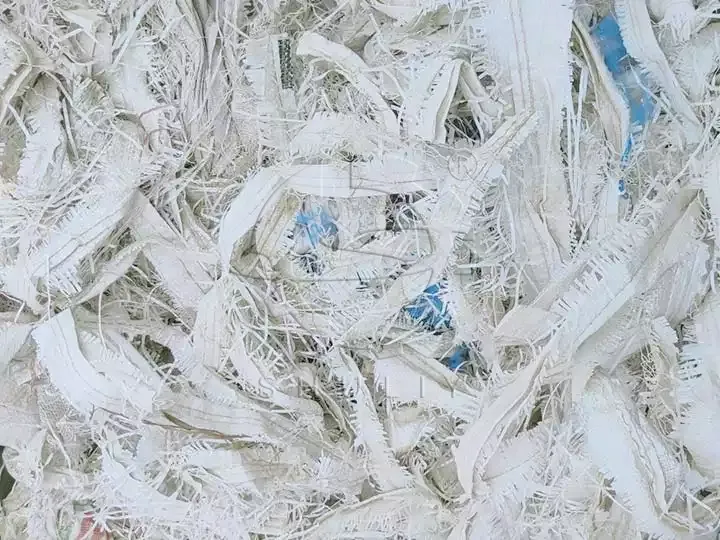

The plastic pelletizing machine is a key equipment in the plastic pelletizing production line, which is used to process waste plastics such as PP, PE, HDPE, LDPE, PVC, PS, etc. into plastic pellets. It can process plastic flakes, plastic bottles, plastic films, plastic bags, plastic buckets, plastic pipes, trimmings generated during the production of plastic products, and so on into plastic gramules. We can recommend the right solution for your raw materials.

Final Product – Plastic Pellets

Through our pelletizers, waste plastics are processed through a series of processes to produce high-quality plastic granules in the end. These pellets are uniform in size and stable in performance, and can be used directly in the manufacture of new plastic products, such as packaging materials, containers, pipes, and so on. Our pelletizing system not only improves the reuse of resources but also provides customers with high-quality recycled materials.

Structure of Plastic Recycling Granulator

The plastic pellet making machine usually includes a feed inlet, automatic feeding device, reducer, heating device, screw, motor and die head. These components work together to complete the whole process of plastic processing.

The forced feeder is generally used when film materials need to be processed, while hard materials usually do not require this device. The screw is the most important part of the extruder and can be adjusted to the required length. Heating units and die heads are available in a variety of types, configured to suit different processing needs.

Working Principle Of Plastic Pelletizing Machine

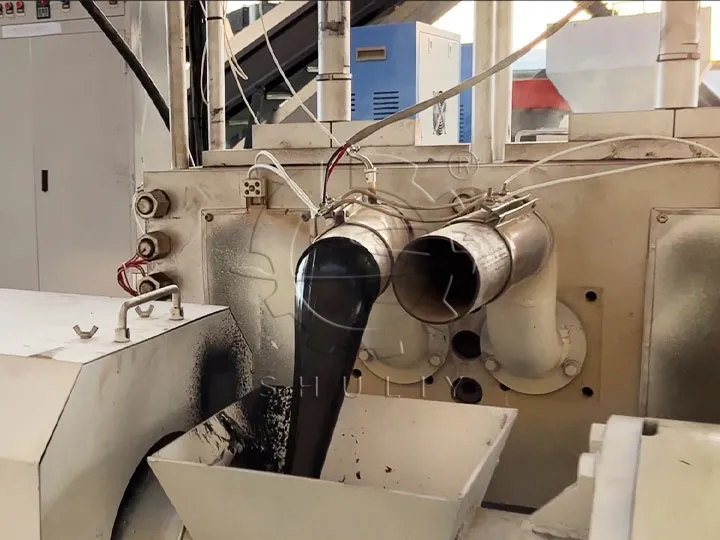

Plastic granulator processes plastic raw materials into granules for reuse by heating and melting the waste plastics, then extruding and cutting them. During the working process, the waste plastic enters the machine from the feeding port, melts through the heating device, and then is transported to the die head through the screw, and is finally extruded into a continuous long strip of plastic. The plastic lengths are cooled and cut to obtain plastic pellets of uniform size.

Advantages and Characteristics of Pelletizer

Conveyor belt with iron removal device: The conveyor belt equipped with an iron removal device effectively prevents metal impurities from entering the pelletizing process and ensures the quality of pellets.

Selective configuration of force feeder: The configuration of the force feeder can be selected according to the characteristics of different raw materials to ensure a stable supply of raw materials and improve production efficiency.

Various pelletizing methods: In addition to the common strand pelletizing method, water ring-cutting pelletizing is also available to adapt to the processing needs of different types of plastics, providing a wider range of options.

Customized design: Our plastic pelletizing machine models are named after the inner diameter of the screw, and the length can be customized according to the specific requirements of customers to meet different production scales and process requirements.

High-quality materials guarantee: Screws are made of 38Lo manganese steel and dies are made of 40Lo to ensure wear resistance and service life, stable production performance.

Intelligent configuration: According to the characteristics of the raw material, recommend the appropriate heating device and die head type to improve production efficiency and finished product quality.

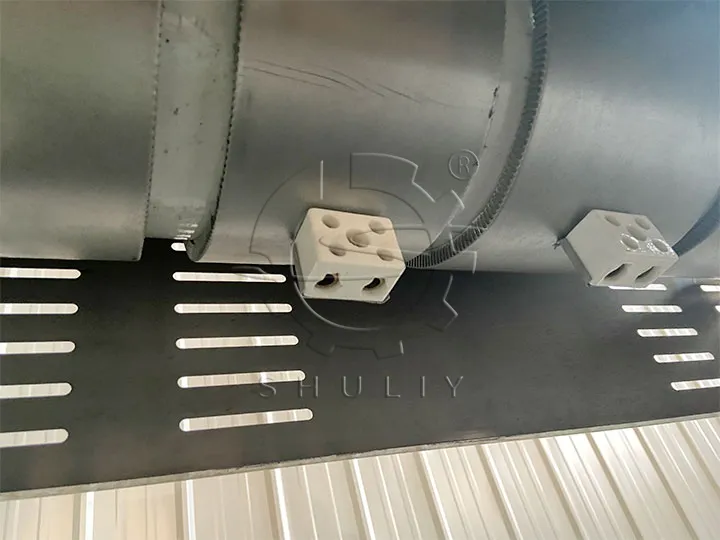

Heating Method Of Plastic Pellet Making Machine

The heating methods of plastic pelletizing machines mainly include electromagnetic heating, ceramic heating, and ordinary electric heating. Different heating methods are suitable for different types of plastics and production needs, but all of them can effectively heat the plastics to the melting state.

Electromagnetic heating: This method has the advantages of fast heating and low energy consumption, and is suitable for production scenarios that require high heating speed.

Electromagnetic heating is characterized by uniform temperature and high control precision, which can effectively improve production efficiency.

Ceramic heating: Ceramic heating is the use of ceramic heating elements for heating. This kind of heating method has the characteristics of good stability, high-temperature resistance, and long service life, which is suitable for occasions with high requirements on heating temperature and long-time continuous heating.

Ordinary electric heating: Ordinary electric heating is a common type of heating method, which generates heat through electric heating elements such as resistance wire or heat pipe to heat the plastic material. This method is simple and easy to operate, the cost is relatively low, suitable for general plastic processing production.

Die Head Of Plastic Pelletizing Machine

Plastic pelletizing machine die head is one of the crucial parts in the production process of plastic granules, its main role is to mold the heated molten plastic material into the desired shape and size of plastic pellets. We have three kinds of electric gear die heads, hydraulic die heads, and screenless slag discharge die heads, which customers can choose according to their production requirements.

Electric gear die head: Electric gear die heads are a commonly used type of die head. This type of die head has a simple structure, is easy to operate, and is suitable for general plastic pelletizing needs. The advantages are stable production and low cost.

Hydraulic mold head: The hydraulic die head is driven by a hydraulic system to control the movement of the extrusion mechanism and realize the extrusion of plastic granules.

It has the advantages of large extruding force, stable work, etc. It is suitable for plastic pelletizing production lines with large demand and large production scale.

Meshless slag discharge die head: The die head is characterized by a screenless design, which discharges the residual impurities and impurities in the plastic raw material through a special slag discharge device.

This type of mold head is suitable for situations where high-quality requirements are placed on plastic granules, and can effectively improve production efficiency and product quality.

Technical Parameters of Pelletizing Machine

| Brand | Shuliy Machinery |

| Product | Plastic pelletizing machine |

| Production capacity | 100kg/h-1000kg/h |

| Pelletizing method | Strand pelletizing, water ring pelletizing |

| Heating method | Electromagnetic heating, ceramic heating, electric heating |

| Mold head | Electric gear die head, hydraulic die head, meshless slag discharge die head |

| Customizability | Can be customized |

| Strand pelletizing diameter | 3mm-4mm |

| Conversion rate | Consumption rates of up to 2% only depend on the quality and cleanliness of the plastic raw material. |

Plastic Pellet Extruder Global Cases

Pelletizing Recycling Machine Helps Iranian Customer To Recycle HDPE

Iranian customer purchased a pelletizing recycling machine for processing HDPE shredded material into plastic pellets from our company. The output of the machine is 500kg/h. The machine has been running successfully and the customer has filmed a video of the machine running for us.

More case details: Waste Plastic Extruder Shipped To Iran For HDPE Recycling

Recycled Plastic Extruder Installation In Oman

The Recycled Plastic Extruder Installation in Oman has been completed. Our Omani customer purchased a crusher, washing machine, and recycled plastic extruder from us to process PP battery cases into recycled plastic pellets. With the on-site assistance of our engineers, all equipment has been installed and is now running smoothly, helping the customer enhance their recycling operations and generate profits.

More case details: Successful Installation Of Plastic Waste Machines For Pelletizing Hard Plastics

Plastic Pelletizing Machine Price

Shuliy Machinery’s plastic pelletizing machines are reasonably priced and offer good value for money. We offer a wide range of models and configurations of plastic granulators to meet the different needs and budgets of our customers.

Whether you are a small-scale plastic recycler or a large-scale manufacturer, we can provide plastic recycling granulators that fit your needs and ensure product quality and performance. At the same time, we also offer flexible customization services to customize plastic granulators according to customers’ special requirements, providing more personalized solutions for customers.