PP HDPE PVC Rigid Plastic Pelletizing Line

Our plastic pelletizing line is used to process rigid plastics such as PP PE HDPE PVC into pellets. The standard capacity of this plastic granulating line ranges from 100kg/h to 500kg/h, which can be customized according to different needs and production scales to meet different customers’ requirements.

Our plastic pelletizing line is used to process rigid plastics such as PP PE HDPE PVC ABS PS into granules. This line usually consists of a series of machines and equipment for handling raw materials, crushing, washing, melting, extruding, cooling, and cutting, and finally processing the plastic into small granules.

These pellets can be used to manufacture a variety of plastic products, such as injection molding, extrusion molding, blow molding, and so on. The standard capacity of this plastic granulating line ranges from 100kg/h to 500kg/h, which can be customized according to different needs and production scales to meet different customers’ requirements.

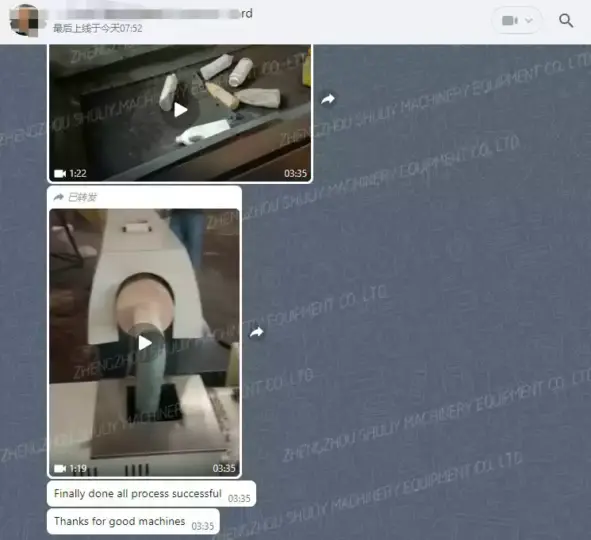

Video Of PVC Pelletizing Line In Action

The plastic recycling processing plant in the video is the factory of our customers in Oman, where our equipment is used to process hard PVC plastic into plastic granules.

Advantages of Plastic Recycling Pelletizing System

- Wide range of applications: our waste recycling plant not only recycles post-consumer plastics but also processes the trimmings and scraps from post-industrial plastics into granules to produce plastic products again.

- Optimized granulation process: We have optimized our plastic granulation process to meet the complete needs of our customers from crushing, and washing to granulating, ensuring that each step is efficient and smooth.

- Customized solution design: According to the customer’s specific needs, raw materials, production capacity, and plant area, we can provide tailor-made production line design to ensure that every detail meets the customer’s actual situation.

- Various pelletizing systems: In addition to the traditional strand pelletizing, we also provide an advanced water ring pelletizing system to further enhance the efficiency and quality of granulating to meet the needs of different customers.

Application of Plastic Flake Pelletizing Line

Our rigid plastic pelletizing line is suitable for recycling various types of plastics, including PP, HDPE, PVC, ABS, PS, PC, and so on. It can not only recycle post-consumer plastics but also process the trimmings and wastes from post-industrial plastics into high-quality granules, which can be used again for the production of plastic products.

For example, our equipment can recycle plastic buckets, plastic bottles, plastic baskets, food containers, electrical shells, car parts, garbage cans, toys, bottle caps, and many other plastic products. If you have the above or other plastics to recycle, you can contact us anytime, our professional sales manager can provide solutions according to your raw materials.

Plastic Granulating Line Process And Related Machines

In the first step of the plastic granulation line, the plastic needs to be crushed using a plastic shredding machine to crush the large plastic material into small pieces suitable for subsequent processing.

The blade of this shredder machine is made of 60Si2Mn, which is sturdy and durable. The screen size is 20-26mm to control the sheet size.

The crushed plastic flakes will enter the plastic chips washing machine, in which the residual impurities, dirt, etc. will be cleaned off to ensure the purity and quality of the plastic.

The cleaned plastic pellets go to the horizontal dryer to remove the water from them by drying to ensure that the subsequent extrusion process can be carried out smoothly and to avoid the influence of water on the quality of the granules.

The centrifugal dryer has a drying rate of 98% and, if fitted with drying pipes, can control moisture to less than or equal to 0.5%-1%.

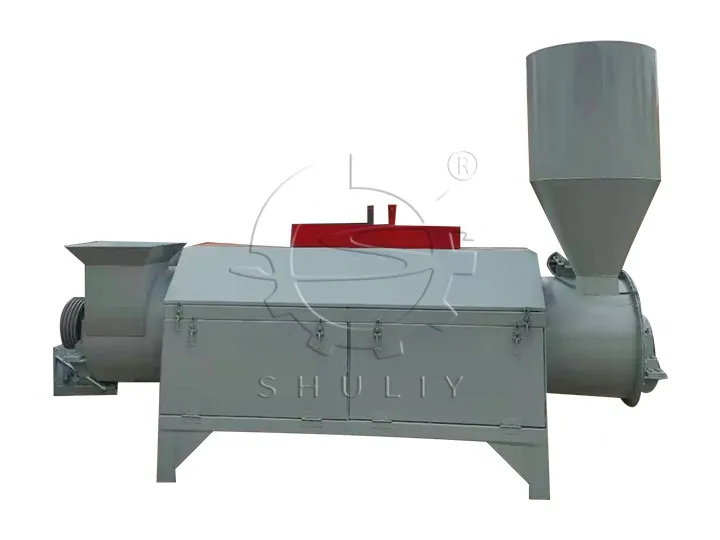

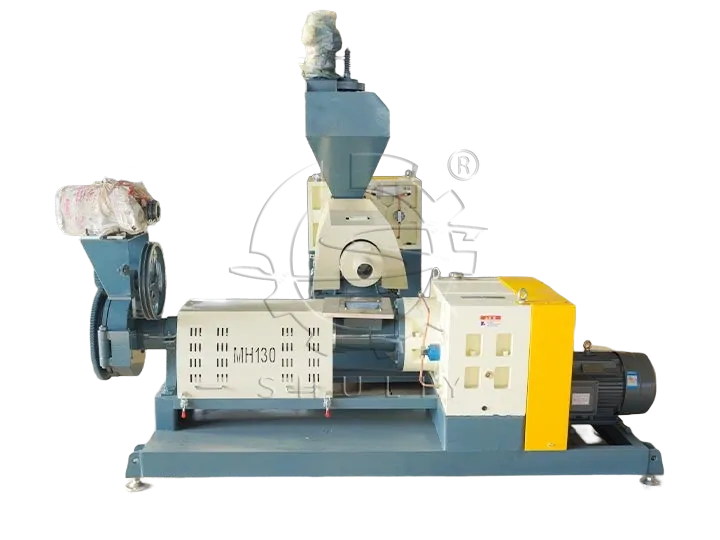

The cleaned and dewatered plastic granules are then fed into a waste plastic granulator, where the plastic is heated and melted, and then extruded through an extruder mechanism, where the melted plastic is extruded into a continuous strip.

Plastic Cooling Tank

The extruded plastic lengths are fed into the plastic cooling tank, where they undergo rapid cooling, allowing the plastic pellets to solidify quickly and maintain their shape and size stability.

The cooled plastic lengths are then cut through the plastic granule cutter, which cuts them into lengths of plastic pellets for subsequent packaging, transportation, and use.

The machine adopts a carbide hobbing knife and cuts out a granule size of about 3mm.

3D Video of Plastic Recycling Processing Plant

Plastic Pelletizing Line Solution Design

Our team focuses on providing customized plastic pelletizing line solution design for our customers. Regardless of the size of the customer’s plant layout, as well as the different production scales, we can design a production line that best suits the customer’s production needs based on their specific needs and requirements.

We have an in-depth understanding of the customer’s production process and product requirements, combined with our rich experience and technical strength, we can customize the plastic recycling line for the customer to improve production efficiency, reduce the production cost, and ensure stable operation of the line and high quality of the finished product.

500kg/H PVC Plastic Pelletizing Line Parameters

Below is an example of a 500kg/h rigid PVC plastic pelletizing line for you to view the details of each machine’s parameters.

| Item | Specification |

| Belt conveyor | Length: 5m Width: 1m Power: 2.2kw |

| Plastic recycling crusher | Model: SLSP-60 Power: 37kw Capacity: 600-800kg/h Knives: 10pcs Knives Material: 65Mn |

| Plastic chips washing machine | 8m tank With chain and motor |

| Plastic dewatering machine | Vertical dewatering machine Power: 7.5kw Horizontal dewatering machine Power: 22kw |

| Auto conveyor | Length: 2.8m Diameter: 2.73m Power: 2.2kw |

| Waste plastic granulator | Host pellet making machine Model: SL-190 Power: 55kw 2.6m screw Heating method: Electromagnetic heating(60kw+80kw) Reducer:315 hardened gear reducer Second pellet making machine Model: SL-180 Power:22kw 1.5m screw Heating ring Reducer:250 hardened gear reducer Screw material: 40Cr Barrel material: 45# steel |

| Plastic cooling tank | Length: 5m Stainless steel |

| Plastic granule cutter | Model SL-200 Power: 4KW With inverter Hob knives |

| Plastic granule storage silo | Material: Stainless steel Power:2.2kw |

We configure the corresponding type of equipment according to different output requirements. In addition to the recycling machines in the above table, customers can also configure auxiliary equipment such as strip-blowing machines and vibrating screens according to their needs.

Strip blowers are usually installed behind the cooling tank to blow dry the water on the plastic strips while vibrating screens are installed after the plastic granule cutter to screen out unqualified pellets to ensure the quality of the final product.

Strand Pelletizing And Water Ring Pelletizing

In the field of plastic granulation, strand pelletizing, and water ring pelletizing are two common and efficient pelletizing systems. Stand pelletizing systems work by extruding molten plastic into strips, which are cooled and then cut into uniform pellets. This method is suitable for a wide range of plastic materials, is easy to operate, and provides consistent granule quality.

Water ring pelletizing systems, on the other hand, cut the molten plastic into granules directly in the water ring after it has been extruded and subsequently cooled and dried. The water ring pelletizing system has a higher degree of automation and is suitable for handling high-viscosity plastics with high production efficiency and uniform pellet shape.

Both granulation methods have their advantages, and customers can choose the most suitable pelletizing method according to their production needs and material characteristics to optimize production results and improve product quality.

Rigid Plastic Pelletizing Line Export Cases

Successful Operation Of Extrusion Line For HDPE Processing In Côte d’Ivoire

Our plastic pellet extruder is running successfully in Côte d’Ivoire and the customer has given us positive feedback on the quality of the recycled HDPE resin already produced by the machine.

More details can be viewed: HDPE Granules Making Machine Running In Côte D’Ivoire

Oman Plastic Scrap Recycling Plant

With the on-site assistance of our engineers, the plastic scrap machine was successfully installed and operated in Oman. The customer in Oman wanted to process PP battery boxes into recycled plastic pellets and we customised the solution for them.

More details can be viewed: Successful Installation Of Plastic Waste Machines For Pelletizing Hard Plastics

Plastic Granulating Line Price

The plastic granulation line price depends on several factors, such as production capacity, customization options, and the number of machines included. Our team offers competitive prices for plastic pelletizing lines while ensuring high-quality equipment and comprehensive services to meet customers’ needs and budgets. We strive to offer transparent pricing and flexible solutions, tailored to specific customer requirements, and designed to provide value and satisfaction throughout the process.